Do companies need perfect data from the start, or is it okay to begin with estimates?

It’s absolutely okay to start with estimates. If businesses wait for perfect data, they’ll lose valuable time. Many companies we’ve worked with begin by using industry averages or sector databases. That gives them a first view of where the major hotspots are and helps them decide where to focus their efforts. These initial estimates can later be replaced with measured data for greater accuracy in assessing the product carbon footprint.

The key is to be transparent. As long as you are clear about what’s estimated and what’s based on primary data, the results are still very useful. A deep dive into product life cycle accounting can provide more robust results by ensuring that greenhouse gas emissions are tracked and reported across the entire product life cycle, distinguishing between different data quality levels.

I always encourage companies to treat their product carbon footprint as a living model. It should evolve as the data gets better, but you can still use it from day one to make smarter choices. Based on carbon footprinting results and hotspot analysis, companies can implement targeted measures to reduce emissions and improve sustainability.

What role do suppliers play in accurate PCF measurement, and how can companies engage them effectively?

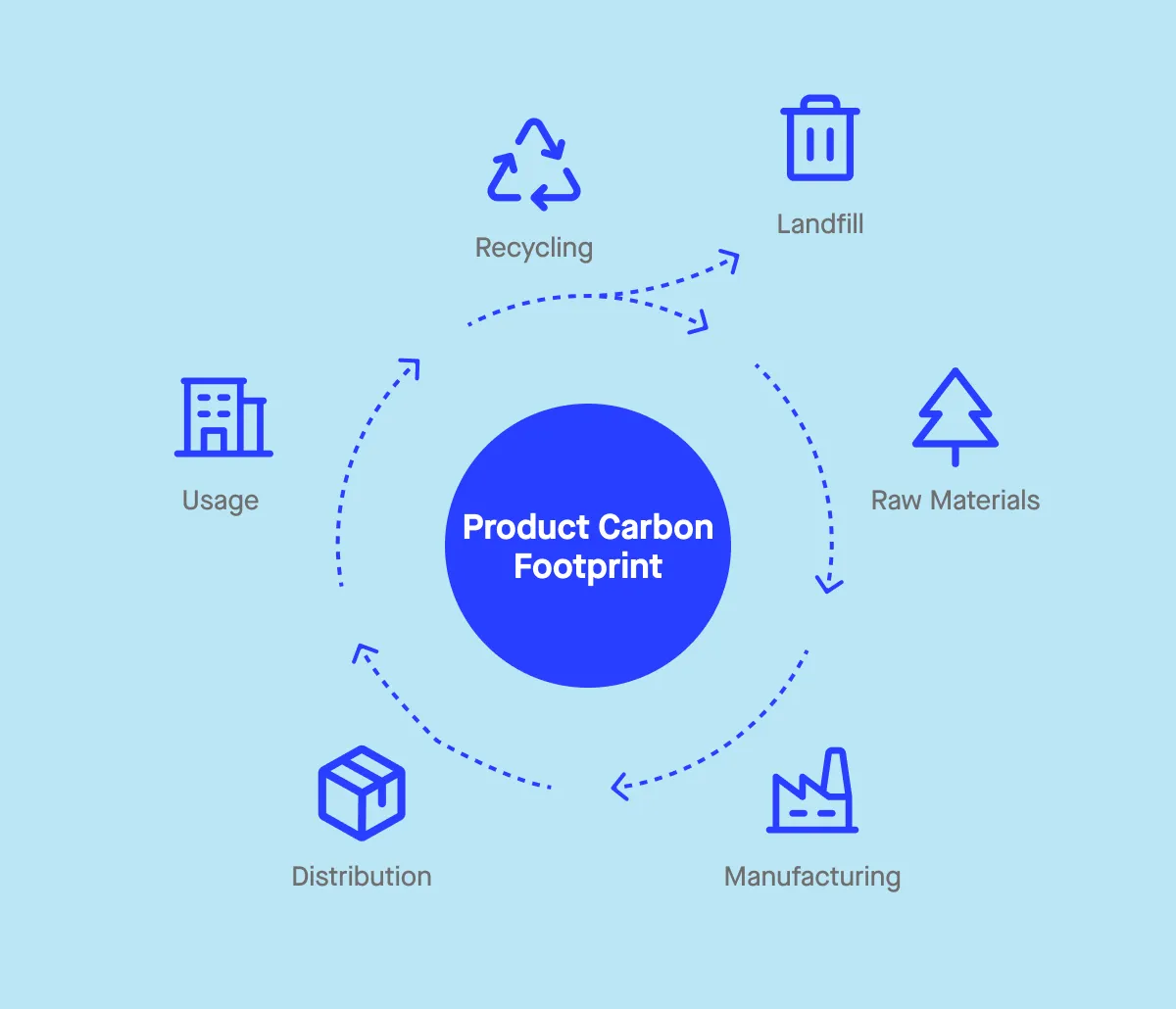

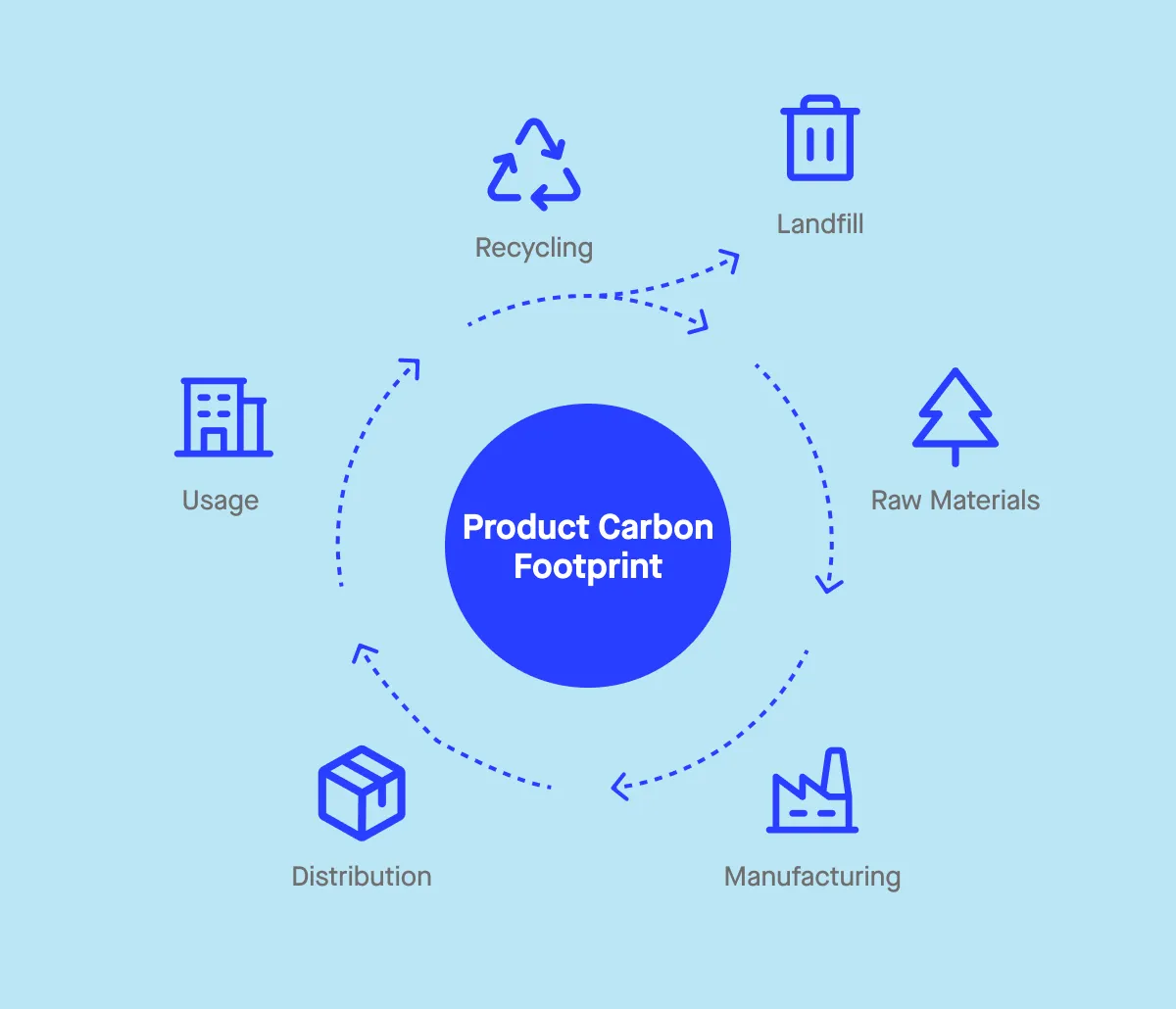

Suppliers play a huge role. For most products, the majority of emissions come from upstream activities, whether that is raw materials, components or energy-intensive manufacturing, all of which contribute to the overall carbon footprint. Without suppliers sharing their data, you only ever see part of the picture.

Engaging suppliers well means making it practical and collaborative. Clear requests, digital tools and feedback on how their input will be used can make a big difference.

Supplier engagement also supports the development of more accurate product carbon footprints by ensuring comprehensive data collection across all lifecycle stages. If suppliers see that the data they provide helps both sides make progress, they’re more likely to engage consistently.

The companies that do this best treat suppliers as partners, not just data providers. They share goals, provide support, and even collaborate on reducing emissions together. That not only improves data quality, it strengthens the whole supply chain.